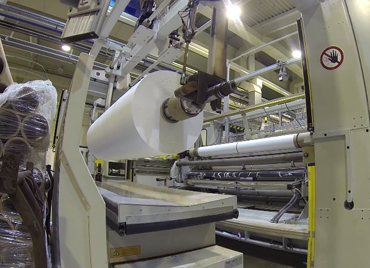

Fatra, Inc. belongs to the world's major processors of plastics (PVC, PE and PET). 70% of the production is exported.

Fatra is using modern technologies for plastics processing in manufacturing centers in Napajedla and Chropyně. It is part of the Agrofert group.

Revenue: 3,7 bn CZK (2016)

Employement: 1 200 (2016)

Fatra uses PROCE55 in logistics and production. The solution is based on the PROCE55 Manufacturing, Warehouse and OEE applications. The project includes the supply of Simatic control systems for the production lines data collecting and SATEC scaling systems. The goal of the project is to identify reserves, increase the productivity and ensure the traceability. The solution is integrated with the SAP ERP system, which is used in Fatra for business operations control.

In the first stage, the solution for the production operations scheduling, production confirmation, monitoring the key KPIs (including OEE, materials inventory) and alerts in the case of outages, was implemented on the key production line. Barcode and mobile terminal based controlled warehouses, batch tracking and shipping control (loading, FIFO, returnable packaging, complaints), including the total shipping weight monitoring are implemented in logistics.

Currently, the solution extends to other production lines and into new areas, such as consignment stores, maintenance, mobile quality control and mobile asset inventory.